-

Chengli Automobile Industry Park

Discussion on the calculation method of the reaction force of the outriggers of truck cranes

How Truck Crane Outriggers Work: Understanding the Math Behind Stability

When a truck crane lifts a heavy load, something important happens. The outriggers push against the ground. These outriggers keep the crane from tipping over. But how much force does each outrigger feel? Let’s find out!

Table of Contents

What Are Outriggers?

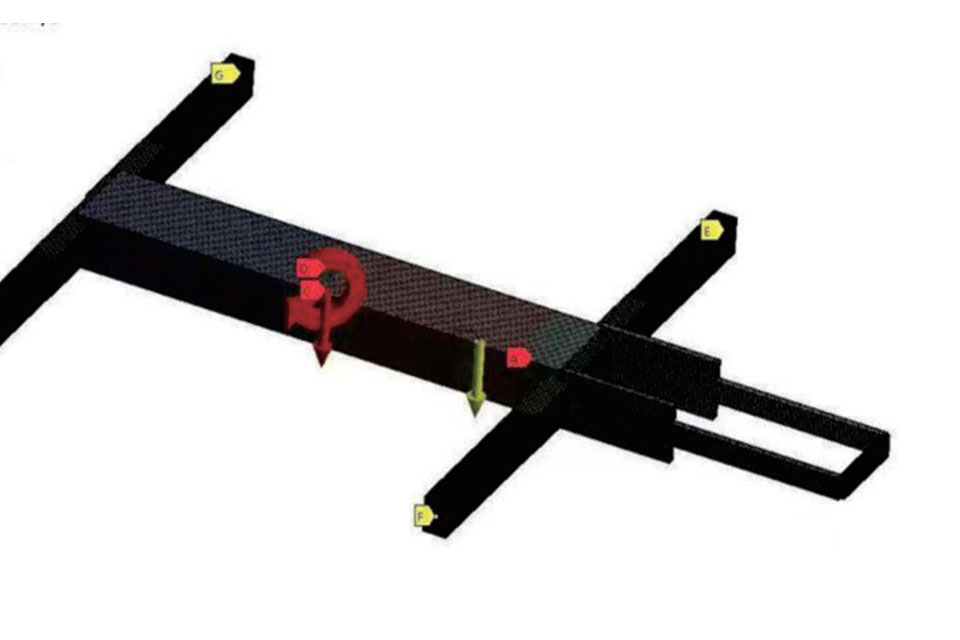

Outriggers are the strong legs that extend from a crane truck. They touch the ground and lift the truck slightly. This makes the crane stable when lifting heavy things.

When picking a for your job, knowing about outrigger forces helps you work safely.

Two Ways to Calculate Outrigger Forces

Engineers use two main methods to figure out these forces:

- Analytical Method – Using math formulas

- Finite Element Method (FEM) – Using computer models

Both help make sure cranes don’t tip over when lifting.

The Math Behind Outrigger Forces

The study we looked at tested these methods. Here’s what they found:

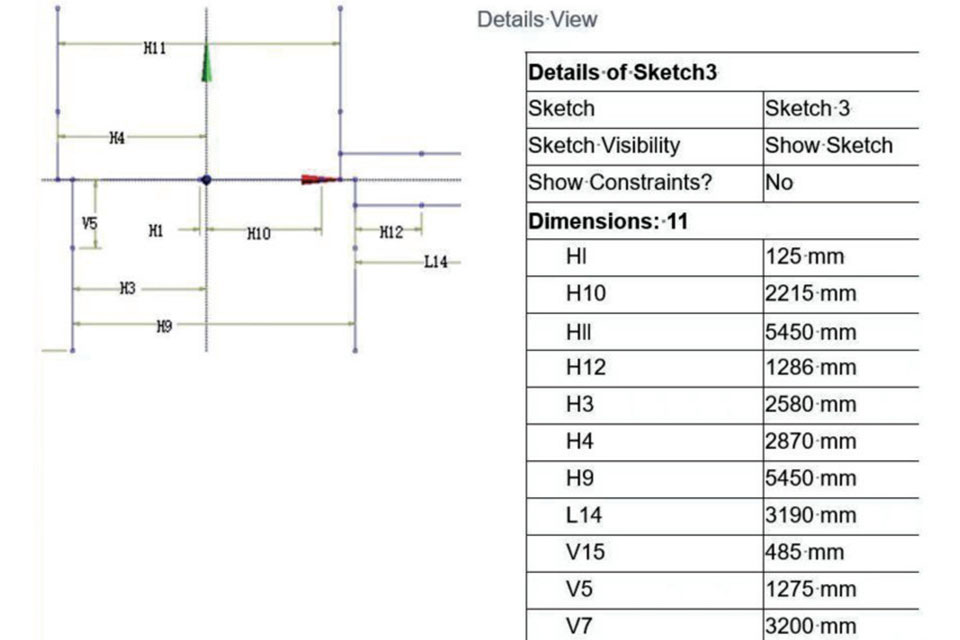

Key Measurements for the Test Crane

| Part | Weight |

|---|---|

| Chassis | 140,000 N |

| Upper structure | 430,000 N |

| Total moment | 1,450,000,000 N·mm |

| The outriggers were set up in a rectangle with: |

- Side-to-side width: 3,200 mm

- Front-to-back length: 2,725 mm

Truck Crane Outrigger Forces: Math vs. Computer Models

Comparing Analytical (Math Formulas) and FEM (Computer Simulation) Methods

High Accuracy (Max Force)

Both methods are very close for the highest outrigger force (< 1% difference in tests).

Differences Vary

Differences are larger (up to 18% in tests) for outriggers with lower forces.

Method Choice Matters

Math is faster for early checks; computer models (FEM) handle more complex details like 5th outriggers.

Case Study: Forces with Boom at 90° (Left Side Load)

Forces shown in Newtons (N).

Key Takeaway

Simple math (Analytical) is good for estimating the biggest force quickly. Detailed computer models (FEM) give a more precise picture of all forces, especially in complex setups or for final safety checks. Using both provides the best results for safe crane design.

What Happens When the Crane Lifts?

When the crane boom points to the side (at 90°), the forces on each outrigger are very different. Let’s look at the numbers:

| Outrigger | Where It Is | Force (Analytical) | Force (FEM) | Difference |

|---|---|---|---|---|

| RA | Front Left | 279,300 N | 279,094 N | 0.07% |

| RB | Front Right | 52,737 N | 64,406 N | -18.12% |

| RC | Rear Right | 5,700 N | 6,398 N | -10.90% |

| RD | Rear Left | 232,263 N | 220,110 N | 5.52% |

| See how the front left outrigger (RA) feels the most force? That’s the one that might fail first if the load is too heavy. |

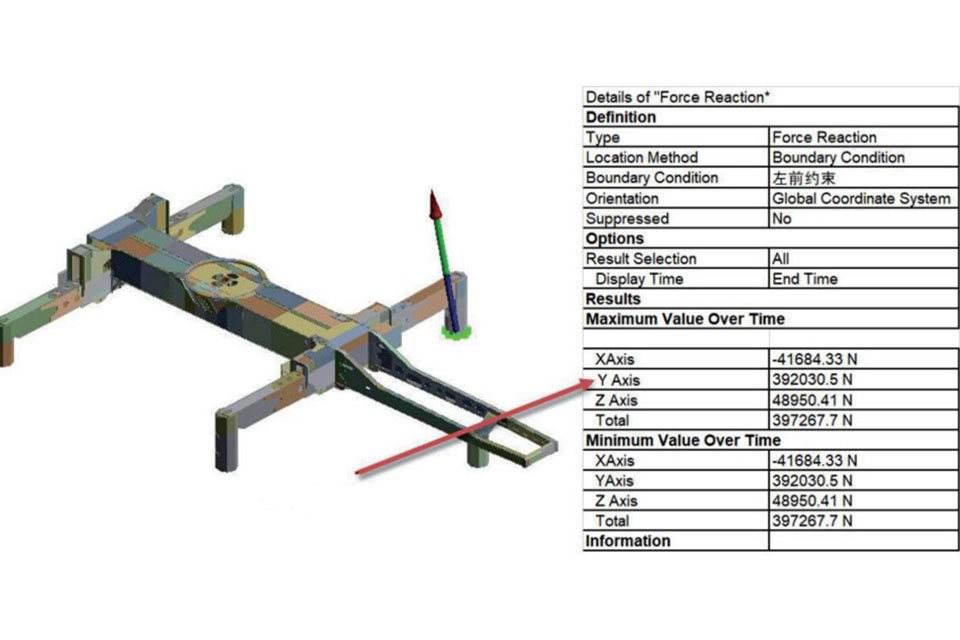

When the Boom Points at an Angle

When the crane boom points at a 45° angle, something interesting happens. One outrigger (RC) lifts off the ground completely!

| Outrigger | Where It Is | Force (Analytical) | Force (FEM) | Difference |

|---|---|---|---|---|

| RA | Front Left | 395,370 N | 392,030 N | 0.85% |

| RB | Front Right | 124,796 N | 135,891 N | -8.16% |

| RC | Rear Right | 0 N | 0 N | 0.00% |

| RD | Rear Left | 49,834 N | 42,089 N | 18.40% |

| When an outrigger lifts off the ground (shows 0 N force), the truck is using only three legs for support. This is called a three-point support case. |

Does Outrigger Layout Matter?

Yes! The study also looked at how outrigger layout affects the forces. They tested:

- Crossed layout – Outriggers not in a perfect square

- Straight line layout – Outriggers in a perfect rectangle

For the main outrigger (RA), the forces were:

- Crossed layout: 285,708 N

- Straight line: 276,001 N

This 3.4% difference shows that how you set up matters!

Which Method Works Better?

Both methods are good but for different reasons:

| What’s Important | Analytical Method | FEM Method |

|---|---|---|

| Speed | Very fast (minutes) | Slower (hours) |

| Accuracy for biggest force | Great (±5%) | Excellent (<2%) |

| Good for which stage | Early design | Final design check |

| What it might miss | Fifth outrigger effects | Nothing major |

| For crane trucks with a fifth outrigger in front, the FEM method works best because it handles this extra complexity. |

What This Means for Crane Work

When using a material handling vehicle like a truck crane:

- The biggest force is almost always on the outrigger opposite from where the boom points

- Computer models (FEM) and math formulas give almost the same answer for the biggest force

- Small forces are where the two methods disagree most

- When designing new cranes, using both methods is smartest

Safety First!

When working with mobile all-terrain cranes, always remember:

- Set up on firm, level ground

- Extend outriggers fully when possible

- Know your crane’s lifting limits

- Don’t exceed the maximum load for any position

Conclusion

Understanding outrigger forces helps engineers build better, safer cranes. The study shows that simple math works well for quick checks, but computer models help catch all the details.

Next time you see a crane lifting a heavy load, you’ll know there’s a lot of math making sure it stays upright!