-

Chengli Automobile Industry Park

Research on the application of aluminum alloy in vans

Aluminum Alloy Vans: Lightweight Solutions for Modern Transport

Have you ever seen a van that looks the same as others but can carry more goods? This is what happens when vans use aluminum alloy parts instead of heavy steel. Let’s talk about how this smart metal is changing vans today.

Table of Contents

Why Aluminum Makes Vans Better

Aluminum is a shiny metal that weighs just 1/3 of what steel weighs. This makes a big difference for vans that need to carry lots of stuff.

The best things about aluminum for vans are:

- Much lighter than steel

- Strong enough to hold heavy loads

- Won’t rust like steel does

- Can be shaped into cool designs

- 100% recyclable when the van gets old

A company called JX5045XXYTG26 tried making their van box with aluminum instead of steel. The results were amazing:

| Part | Steel Weight | Aluminum Weight | Weight Savings |

|---|---|---|---|

| Van Box (4080×2300×2200mm) | 890 kg | 610 kg | 32% |

This means the van can carry 280 kg more stuff without breaking any rules!

Aluminum Alloy Vans: Weight Reduction Impact

Types of Aluminum Used in Vans

Not all aluminum is the same. Smart engineers pick special types for different van parts:

| Aluminum Type | What It Contains | Where It’s Used | Why It’s Good |

|---|---|---|---|

| 5052-H24 | Aluminum + Magnesium | Side panels, roof | Bends without breaking |

| 6063-T6 | Aluminum + Magnesium + Silicon | Beams, pillars | Strong for its weight |

| 6082-T6 | Aluminum + Magnesium + Silicon | Main structure | Extra strong for heavy loads |

These special mixes help make parts that won’t bend or break when the van is full.

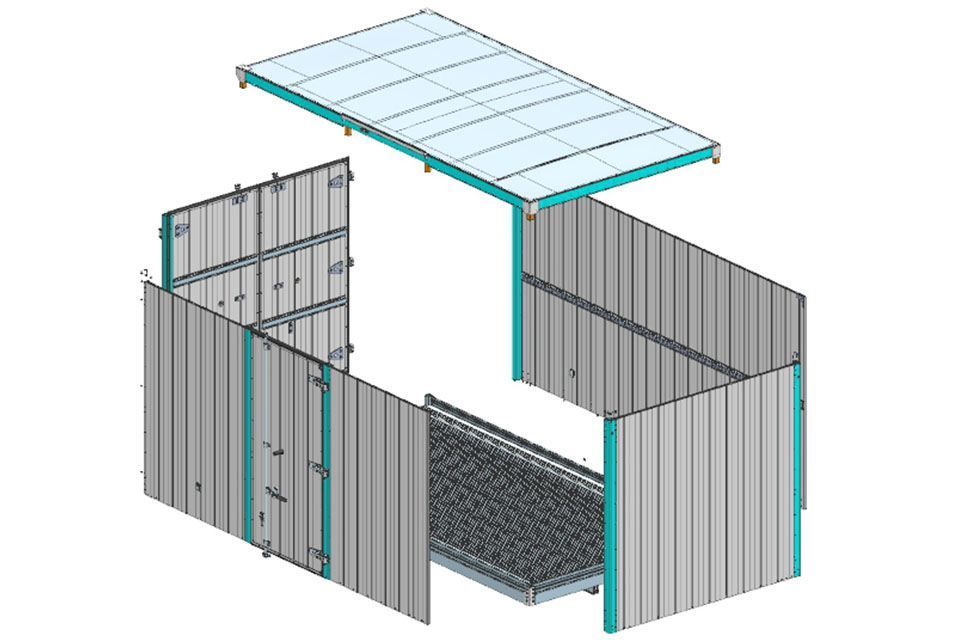

How They Make Aluminum Van Parts

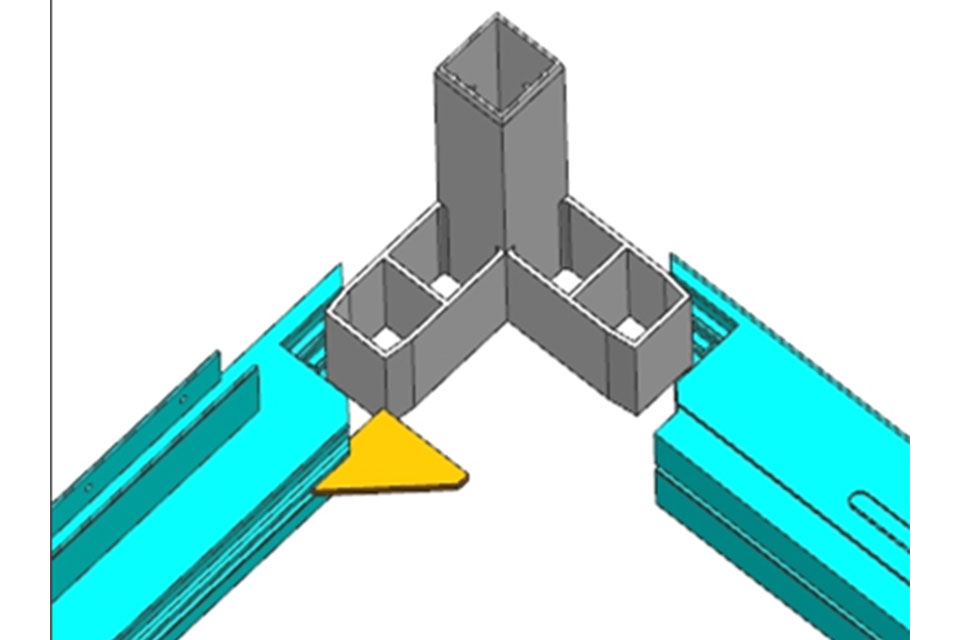

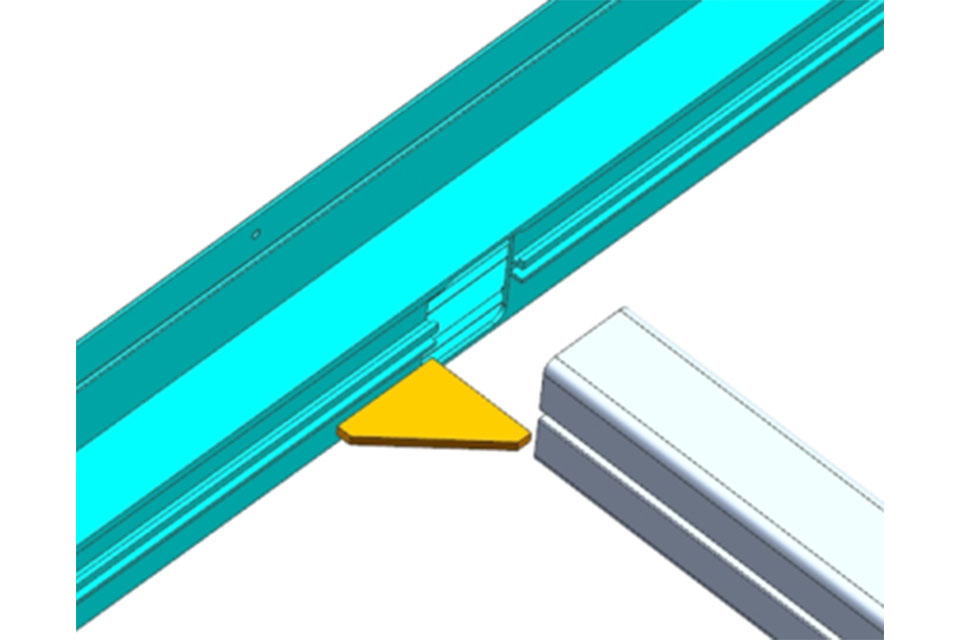

The cool thing about aluminum is how they shape it. They push hot aluminum through special holes (like Play-Doh) to make beams with perfect shapes.

This process called “extrusion” lets them make parts that are:

- Hollow inside to save more weight

- Complex shapes that steel can’t make

- Stronger in the right places

- Ready to connect to other parts

When they put the van together, they don’t weld much because welding makes aluminum weaker. Instead, they use:

- Special bolts

- Rivets (like strong staples)

- Puzzle-like connections where parts lock together

This makes the van super strong even though it’s light.

Real Benefits of Aluminum Vans

When vans lose weight, good things happen:

For Regular Gas/Diesel Vans:

- Every 10% weight reduction saves 6-8% fuel

- Less fuel means less smoke and pollution

- Vans can carry more goods in one trip

For Electric Vans:

- Removing 100kg of weight adds 6-11% more driving range

- This helps solve the “will I run out of power?” worry

- More trips on a single charge saves time and money

For companies with many vans, these savings add up fast!

Check Out Our Other Flatbed Truck Options

If you’re interested in lightweight commercial vehicles, our Electric Cargo Truck range complements aluminum van technology perfectly. For businesses handling liquids, our Liquid Transport Truck models also benefit from aluminum construction techniques.

Challenges to Overcome

Making aluminum vans isn’t all easy. There are some problems to solve:

- Cost – Aluminum costs more than steel upfront

- Different skills needed for building and fixing

- Joining methods need special care

But as more companies make aluminum parts, the price will come down. And the fuel savings help pay back the extra cost over time.

What’s Next for Aluminum Vans?

Engineers are working on even better aluminum for vans:

- Stronger alloys that let vans carry even more

- Mixed materials using aluminum with other lightweight options

- Smarter designs that use less material while staying strong

As zero-emission vehicle rules get stricter, lightweight vans will become more important. Aluminum vans aren’t just a cool idea—they’re the future of moving goods in our cities.