-

Chengli Automobile Industry Park

Finite element analysis of wave-breaking plates in tank trucks at different filling rates

Safety First: How Wave-Breaking Plates Work in Tank Trucks

Have you ever seen a big truck that carries liquid? These trucks need special plates inside to keep the liquid from moving too much. Let’s learn how these wave-breaking plates work!

Table of Contents

What Are Wave-Breaking Plates?

Wave-breaking plates are strong metal walls inside tank trucks. They split the tank into smaller parts. This helps keep the liquid from moving too much when the truck stops fast.

Why do we need these plates? When a tank truck stops quickly:

- The liquid inside keeps moving forward

- This can push the truck and make it hard to control

- It can damage the tank

- The truck might tip over!

How We Studied These Plates

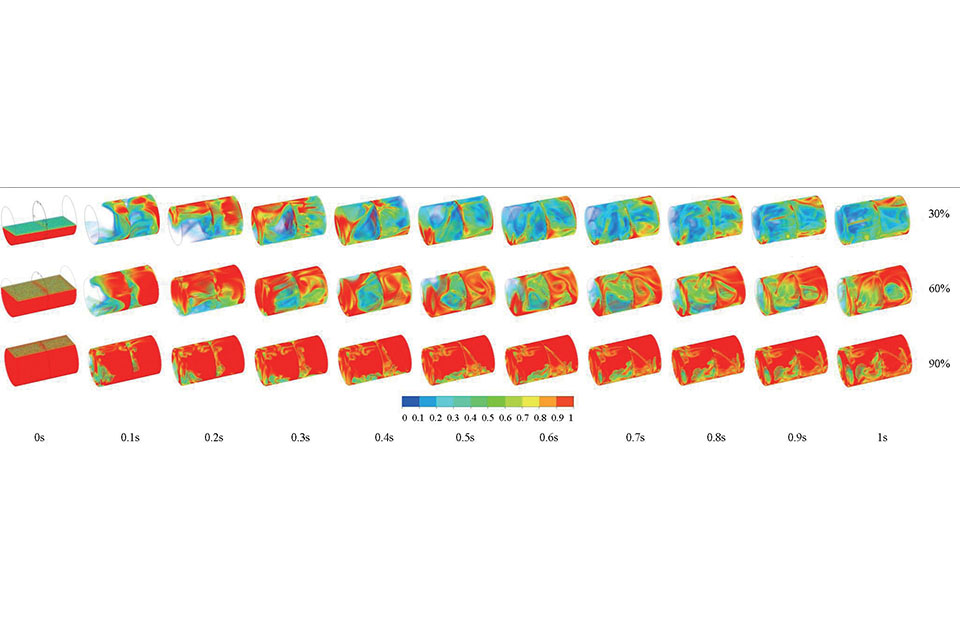

To see how well these plates work, scientists used computers to test them. They looked at tanks filled to three different levels: 30%, 60%, and 90% full.

They set up a test like this:

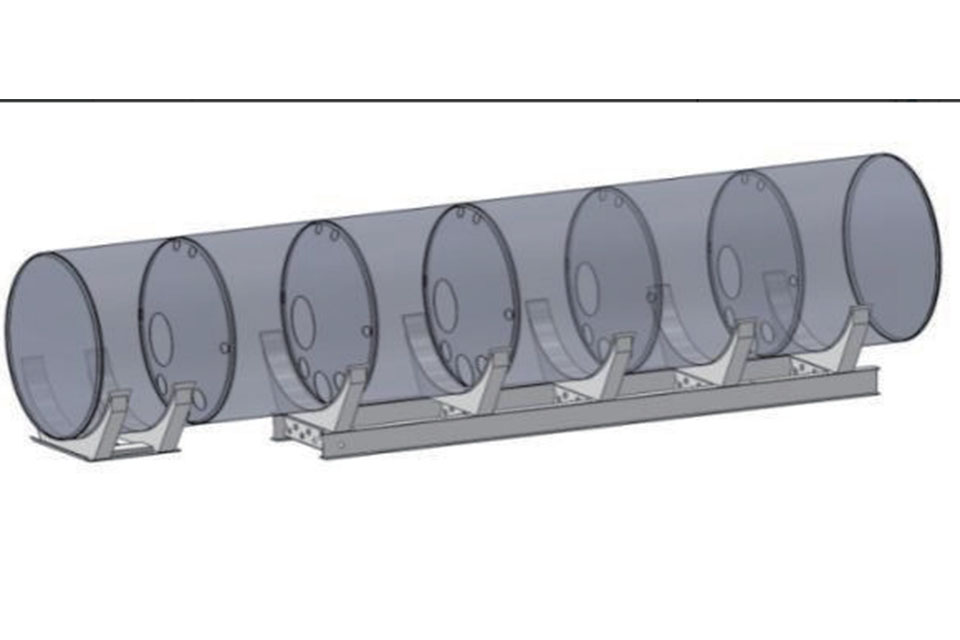

- Tank size: 8,580 mm long and 873 mm wide

- Truck speed: 50 km/h (then quick stop!)

- Stopping power: 5.08 m/s² (that’s a fast stop!)

What We Found

Liquid Movement

When the truck stops fast, the liquid hits the plate hard. But the plate helps stop the liquid from all moving to the front.

Here’s what happens at different fill levels:

| Fill Level | How Liquid Moves | Where Pressure Hits Hardest |

|---|---|---|

| 30% | Very splashy! | Top holes at first, then bottom |

| 60% | Less splashing | Bottom holes after 0.3 seconds |

| 90% | Small waves | Even pressure on lower part |

Tank Truck Safety: Wave Plate Stress at Different Fill Levels

Understanding Liquid Sloshing Impact During Braking

Key Findings

Peak Stress Time:

Plates experience maximum force 0.1 seconds after emergency braking begins.

Highest Risk:

Plates endure ~2-3 times more stress at 30% fill compared to higher levels.

Recommendation:

Maintain ~10% empty space (90% fill) for optimal balance of safety and efficiency.

Peak Stress on Wave Plates by Fill Rate

Data based on Finite Element Analysis of Tank Truck Wave-Breaking Plates.

artjs]: Chart generated using Chart.js library.

artjs]: Chart generated using Chart.js library.

Stress on the Plates

The plates get pushed hardest at 0.1 seconds after braking starts. This is when drivers need to be most careful!

| Fill Level | How Hard Plates Get Pushed | How Plates Bend |

|---|---|---|

| 30% | 228.64 MPa | A lot – 2× more than at 60% fill |

| 60% | ~114.32 MPa | The least bending |

| 90% | ~76.21 MPa | Small, even bending |

| Good news! Even at the hardest push (228.64 MPa), the plates don’t break. They’re made of Q235 steel that can handle up to 235 MPa of force. |

How to Keep Tank Trucks Safe

Based on what we learned, here are some tips:

- Don’t drive with tanks less than 40% full if possible

- Leave about 10% empty space at the top

- Be extra careful when braking from high speeds

- Make sure wave-breaking plates are strong enough

- Use curved plates instead of flat ones

Why This Matters for

If you work with liquid transport trucks, knowing how wave-breaking plates work helps keep everyone safe. These plates are important parts of tank trucks for hazardous materials too.

Special Equipment Used

Scientists used some cool tools to study these plates:

- VOF model: A computer program that shows how liquid and air move together

- ANSYS software: Makes detailed pictures of how the liquid pushes on the plates

- Flow-structure coupling: Shows how the liquid and plates affect each other

Things We Learned

- The most dangerous time is 0.1 seconds after braking

- Tanks 30% full have the most splashing and plate bending

- Tanks 60% full have the best balance of safety and carrying capacity

- Tanks 90% full have more even pressure but less space for liquid to move

What This Means for Truck Safety

Tank truck drivers should:

- Know their trucks have these special plates

- Remember that stopping too fast can still be dangerous

- Know that carrying less liquid (like 30% full) isn’t always safer!

Next Steps

Scientists want to study:

- How multiple plates work together

- What happens when turning corners

- How different liquids (thicker or thinner) affect the plates

- How to make better plate designs

With better wave-breaking plates, tank trucks can carry liquids more safely on our roads!