-

Chengli Automobile Industry Park

Discussion on maintenance-free products and related technologies for semi-trailer axles

Maintenance-Free Semi-Trailer Axle Technology: Cutting TCO and Boosting Safety

When you own a semi-trailer, the costs add up fast. Fuel, tolls, and wages are just the start. What many owners don’t see coming are the hidden costs of axle maintenance. Maintenance-free axle systems can solve this problem, helping trucks stay on the road longer while costing less over time.

Table of Contents

Why Maintenance-Free Axles Matter

Regular semi-trailer axles need lots of care. You must:

- Check wheel bearings often

- Replace lubricants

- Inspect brake parts

- Take wheels off for checks (“wheel removal”)

This all costs time and money. When trucks sit in shops, they don’t make money.

With maintenance-free axles, you get:

- Lower total ownership costs (TCO)

- Better safety records

- Higher truck availability

- Fewer roadside breakdowns

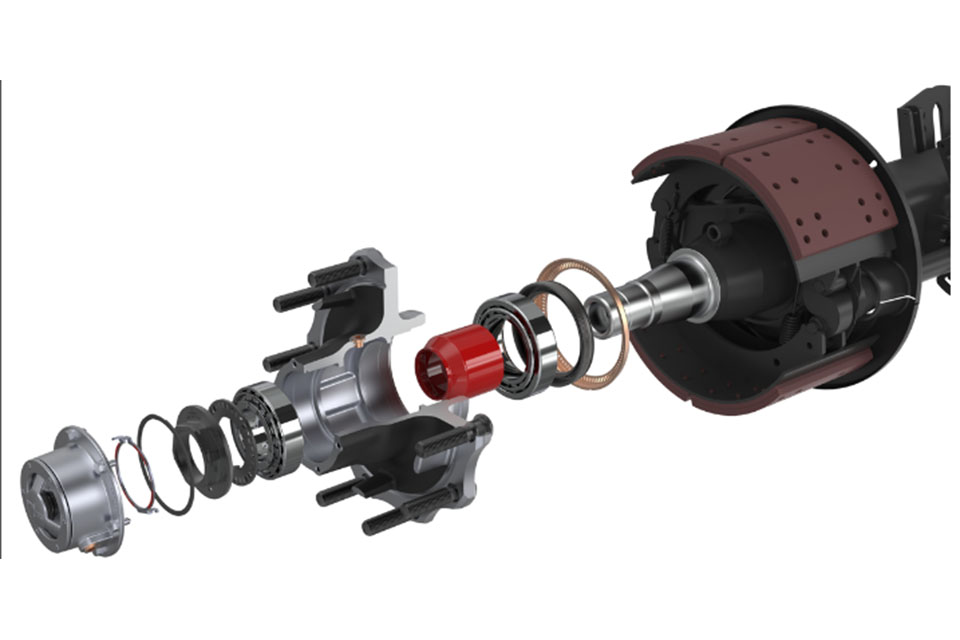

How Maintenance-Free Axles Work

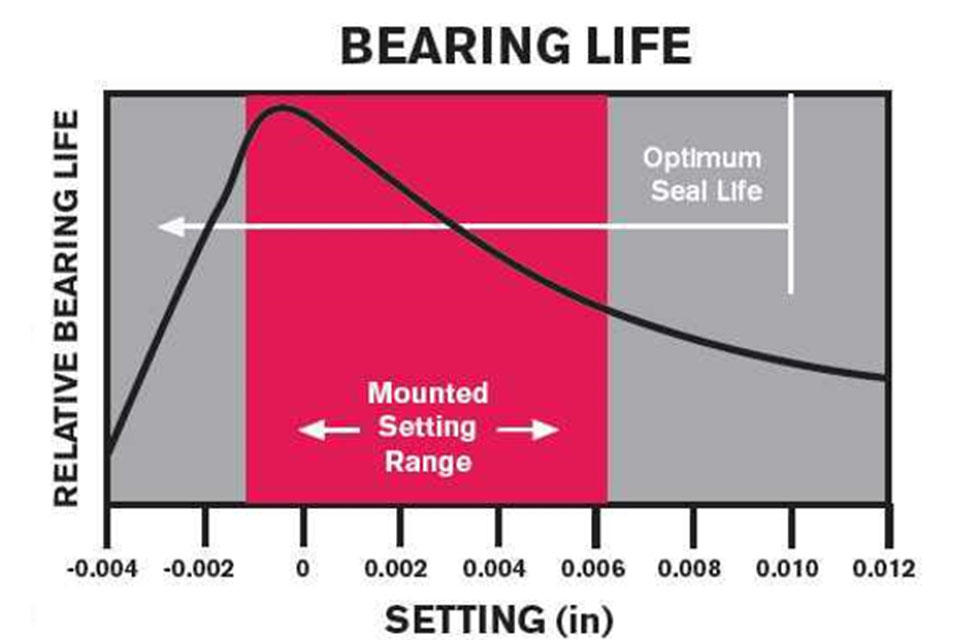

The key to maintenance-free axles is bearing life. Bearings work best when they have the right amount of space (called “clearance” or “endplay”). This space should be between -0.025mm and +0.152mm.

When bearings have this perfect space, they last much longer. There are three main ways to get this right:

1. High-Precision Axle Nuts

This method uses special nuts that can set the bearing space very precisely.

Popular products include:

| Product | Company | Precision | Maintenance Cycle |

|---|---|---|---|

| Zip-Torque | Stemco (USA) | 0.001″ | Needs manual checking |

| Precision 320 | Hendrickson (USA) | 0.00026″ | 7 years/110,000 km |

| 800K Hub | BPW (Germany) | 0-15° rotation | 3 years/80,000 km |

The Hendrickson system stands out because it uses an outside brake drum design. This means you can fix brakes without taking the wheels off – a huge benefit!

Semi-Trailer Axles: Maintenance-Free Benefits

Discover how modern axle technology saves money, extends lifespan, and improves safety.

Lower Total Cost (TCO)

Up to 30%+ Savings

Reduced maintenance, fewer breakdowns, less downtime.

Extended Lifespan

3-7+ Years

Longer component life with optimized lubrication and sealing.

Improved Safety

Reduced Failures

Consistent performance, fewer bearing issues, better reliability.

Lubrication Matters: Oil vs. Grease

Theoretical bearing fatigue life under ideal conditions (13t axle load, 95 km/h equivalent).

Warranty & Maintenance Periods (Examples)

*Kilometers shown represent typical warranty periods, actual lifespan may vary.

How Maintenance-Free is Achieved

Precision Nuts

Uses highly accurate nuts for initial bearing setup. May still need checks. (e.g., Stemco, Hendrickson)

Bearing Units

Pre-assembled units with set clearance. Higher replacement cost if fails. (e.g., SKF, Timken)

Set-Right System

Precisely matched components (hub, bearings, spacer) for automatic clearance. Most robust. (e.g., Conmet)

2. Pre-Set Bearing Units

These come with the perfect bearing space already set at the factory.

Examples include:

- SKF THU2 (Sweden)

- Timken UniPac (USA)

- FAG THU (Germany)

These units come pre-sealed and pre-greased. They offer 3 years or 50,000 km of maintenance-free operation.

While simple to install, they have downsides:

- High replacement costs

- Can’t mix-and-match parts

- Need special tools for installation

- Might fail sooner on rough roads

3. The Set-Right System Approach

This is the most complete solution. It uses all matched parts that work together perfectly.

Key products include:

| Product | Company | Features | Maintenance Period | Key Benefit |

|---|---|---|---|---|

| Preset | Conmet (USA) | Oil lubrication, sight window | 3 years/50,000 km | Works in extreme temps |

| Preset Plus | Conmet (USA) | Advanced sealing | 5 years/80,000 km | Lower TCO |

| 800K | BPW (Germany) | Maze sealing, separate lube spaces | 3 years/80,000 km | Great for rough roads |

Oil vs. Grease: The Big Difference

One major finding: oil lubrication lasts much longer than grease. Testing shows:

- Grease lubrication: 52,300 hours (about 5 million km)

- Oil lubrication: 191,000 hours (about 18 million km)

That’s 3.6 times longer life with oil! The Conmet system uses this to great effect, with a clear window to check oil condition.

Choosing the Right Technology

Pick your system based on your needs:

- For extreme temperatures: Conmet Preset with oil lubrication

- For rough roads: BPW 800K with maze sealing

- For cost-conscious fleets: Hendrickson with outside brake drums

- For standard operations: Any maintenance-free system beats traditional axles

The Outside Drum Advantage

Tractor units for semi-trailers paired with outside brake drum designs have a big edge. With traditional “inside” drums, you must remove the hub to fix brakes. Outside drums mean:

- Brake service without wheel removal

- Hub system stays sealed

- No dirt gets into bearings

- Longer bearing life

What Users Are Saying

Fleet operators using maintenance-free systems report:

- 30% lower maintenance costs

- Fewer roadside breakdowns

- Better uptime and truck availability

- Reduced risk of catastrophic failures

Which System Is Best?

The Set-Right approach (like Conmet Preset) offers the most benefits:

- Parts work together as a system

- No manual adjustments needed

- Oil lubrication for longest life

- Visual inspection without removal

- Works in all climates

For heavy-duty hauling, the BPW 800K system handles the toughest conditions with its maze sealing design.

Conclusion

Maintenance-free axle technology isn’t just nice to have – it’s a smart business move. By picking the right system, semi-trailer owners can:

- Cut total costs significantly

- Improve safety

- Keep trucks on the road longer

- Avoid surprise breakdowns

The best systems combine oil lubrication, outside brake drums, and precision manufacturing. While the upfront cost may be higher, the savings over time make maintenance-free axles well worth the investment.

When buying your next semi-trailer, consider these technologies – your bottom line will thank you!