-

Chengli Automobile Industry Park

Design and research of air pressure brake system for a fire truck

How Air Pressure Brake Systems Keep Fire Trucks Safe

Fire trucks need strong brakes that work every time. When a fire truck races to an emergency, it must be able to stop quickly and safely. This article looks at how air pressure brake systems are made for fire trucks.

Table of Contents

Why Fire Truck Brakes Matter

Fire trucks are big and heavy. They carry water, equipment, and firefighters. A typical fire truck weighs about 13,000 kg (or 28,660 pounds). When something this heavy moves fast, it needs really good brakes to stop.

The brake system in a fire truck uses air pressure instead of the liquid brake fluid that cars use. This helps the big truck stop better.

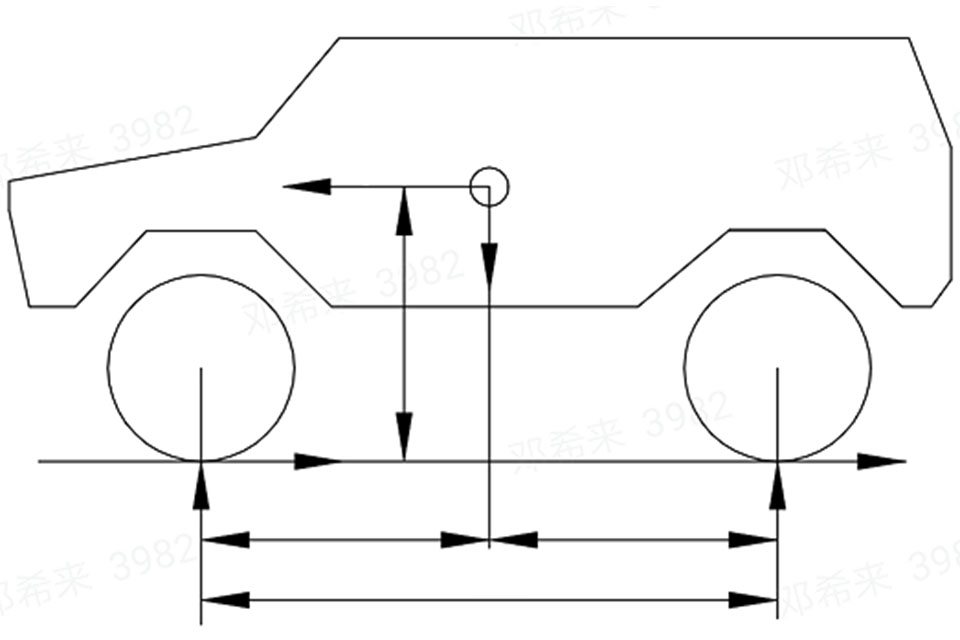

How the Fire Truck is Built

Before making the brakes, engineers need to know some important things about the fire truck:

| Part | Measurement |

|---|---|

| Total Weight | 13,000 kg |

| Wheelbase (distance between axles) | 3.65 m |

| Distance from center of gravity to front axle | 2.15 m |

| Distance from center of gravity to rear axle | 1.50 m |

| Height of center of gravity | 1.10 m |

| Tire rolling radius | 0.52 m |

These numbers help engineers figure out how strong the brakes need to be.

Fire Truck Brake System: Key Data

Air Reservoir Capacity

Total Capacity: 75 Liters

How Strong Should the Brakes Be?

Engineers do math to find out how much braking power is needed. They figure this out for different situations:

- Normal braking on a flat road

- Emergency braking when the truck needs to stop fast

- Parking on hills so the truck doesn’t roll away

For the front wheels, the brakes need to handle 66,457 Newtons of force, which means each wheel needs brakes that can create 17,278 Newton-meters of torque.

For the back wheels, the brakes need to handle 34,343 Newtons, which is 9,220 Newton-meters of torque per wheel.

When parked on a 22° slope (which is pretty steep), the brakes need to hold 47,724 Newtons to keep the truck from rolling.

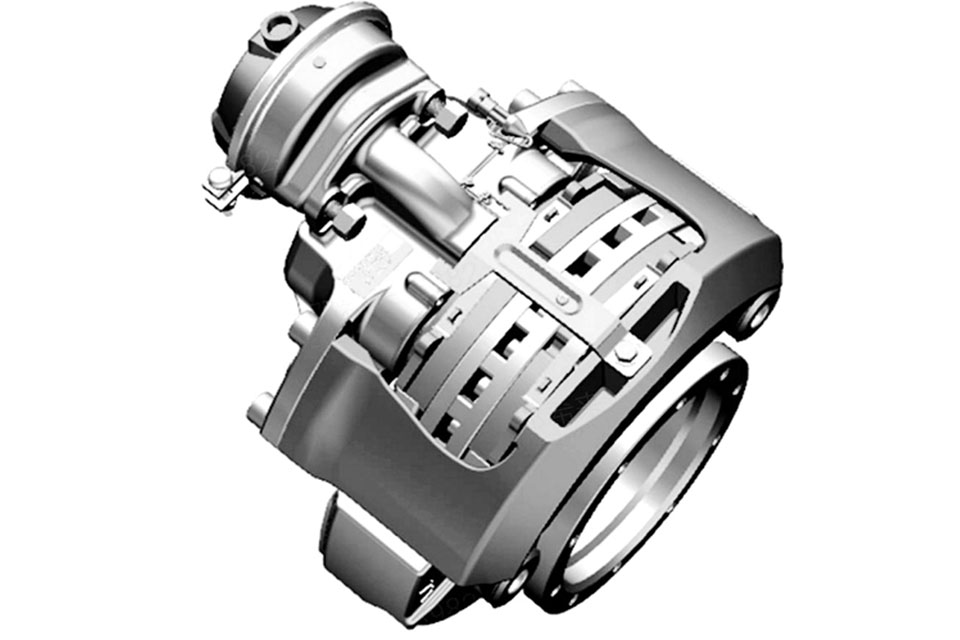

Choosing the Right Brakes

After doing these calculations, engineers pick brakes that are strong enough. For this fire truck, they chose:

Front Axle Brakes:

- Type: Disc brakes with 24-type air chambers

- Brake efficiency factor: 0.8

- Leverage ratio: 16

- Effective brake radius: 0.16 m

- Push rod force: 11,000 N

Rear Axle Brakes:

- Type: Disc brakes with 20-24-type air chambers

- Brake efficiency factor: 0.8

- Leverage ratio: 16

- Effective brake radius: 0.16 m

- Push rod force: 8,000 N for driving, 11,000 N for parking

These brakes can create more torque than needed, which is good for safety:

- Front axle: 20,275 N·m (stronger than the needed 17,278 N·m)

- Rear axle: 13,478 N·m (stronger than the needed 9,220 N·m)

- Parking: 20,275 N·m (stronger than the needed 12,408 N·m)

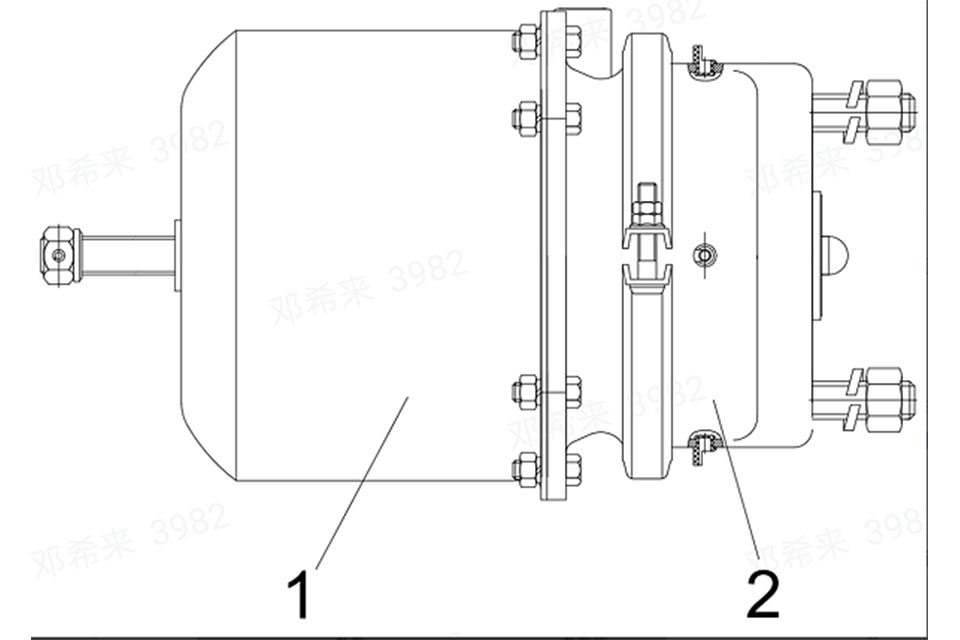

Air Tanks for the Brakes

Air brakes need compressed air to work. The air is stored in tanks called air reservoirs. Engineers need to figure out how big these tanks should be.

For this fire truck, they calculated:

- For normal braking (5 cycles): At least 34.5 liters needed

- For parking braking (2 cycles): At least 6.46 liters needed

- For emergency braking on slippery roads: At least 57.54 liters needed

To be safe, they chose to use three 25-liter tanks, giving a total of 75 liters – more than the minimum needed.

Air Compressor Selection

The air compressor fills the tanks with air. It needs to make enough air to keep the brakes working.

The minimum air flow needed was calculated to be 225.17 liters per minute. The engineers chose a compressor that can provide 275 liters per minute when the engine is running at 1,875 rpm.

This compressor can fill the tanks from empty to the minimum pressure needed to start driving in just 0.154 minutes (about 9 seconds).

Testing the Brake System

After designing and building the brake system, it was thoroughly tested:

- Performance tests to make sure it meets all safety standards

- Reliability tests where the truck drove for 20,000 kilometers (about 12,427 miles) to make sure nothing wore out or broke

All tests showed that the brake system worked well and met all the required safety standards.

Why Air Brakes Are Great for Fire Trucks

Air brake systems have several advantages for Emergency Rescue Fire Trucks:

- More powerful than hydraulic brakes for big vehicles

- Fail-safe design – if there’s a leak, the brakes apply automatically

- Multiple separate systems so if one fails, others still work

- Work well with trailer brakes if the fire truck needs to pull equipment

Most Heavy-Duty Emergency Rescue Vehicles use air brakes because they’re safer and more reliable for large trucks.

Conclusion

Designing air pressure brake systems for fire trucks involves careful calculations, smart choices, and thorough testing. Engineers need to consider the truck’s weight, how it will be used, and safety standards.

The brake system described here has more braking power than needed and more air capacity than required. This extra margin makes the Rescue Fire Truck for Emergency Response safer and more reliable when firefighters need to respond to emergencies.

When fire trucks speed to an emergency, everyone needs to know they can stop safely. Good air brake systems help make sure that happens.